TIME DWM-3G Multi-functional Tribometer

零售价

市场价

I want to make an inquiry

重量

kg

库存

隐藏域元素占位

- Product Detail

- Specifications

- Videos

-

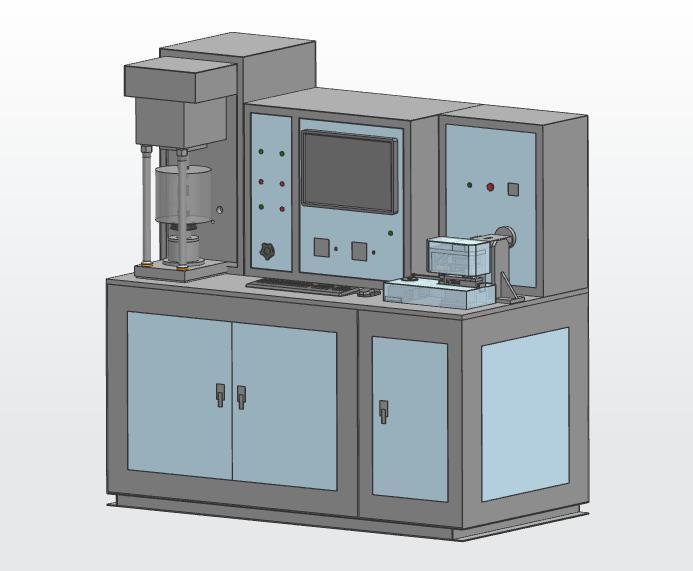

- Commodity name: TIME DWM-3G Multi-functional Tribometer

The DWM-3G multifunctional friction tribometer is divided into two types of functions: a high-temperature multifunctional rotating friction module and a low-load reciprocating friction and wear testing module. This machine uniquely integrates these two functions into a single instrument, covering both types of motion modes for friction and wear testing, making it highly powerful. It is an ideal device for testing in universities and research institutes.

The rotary module, which operates through sliding friction, is used to evaluate the performance of engineering plastics, powder metallurgy, and alloy bearings under specified test conditions. It can be tested at temperatures ranging from room temperature to 800℃, under various conditions including oil-free lubrication, oil-lubricated, and changes in load, speed, time, friction pair materials, surface roughness, and hardness. The module can measure material temperature rise and friction coefficient values.

The reciprocating module features a unique lever loading structure, designed for use in reciprocating friction tests. International brands such as FLEX, PCS, and PLINT also employ a similar lever loading method. The working platform is equipped with a servo motor that controls the installation of a worktable on high-precision rails, enabling smooth lateral movement to ensure the linear reciprocating motion of the test sample during the experiment. The maximum reciprocating displacement is 40mm, and the reciprocating speed can be adjusted.

The fixture uses a sample chuck, and the fixture is connected to an S-type friction force sensor. During the test, the measured friction force is collected and displayed in the corresponding column of the computer software

This machine can realize the full digital adjustment of loading force value, linear reciprocating displacement and reciprocating speed to meet the different test needs of customers.

All the motors used in this machine are Panasonic AC servo motors and controllers, featuring a wide speed range, high torque at low speeds, and low noise. The measurement parameters include test force, friction force, test time, and spindle revolutions. When any parameter exceeds the preset value, the corresponding alarm light will illuminate, and the spindle will stop rotating. All test parameters can be displayed on the digital display device and computer screen, recording the temperature-time curve, friction force-friction coefficient-time curve, and test force-time curve.

Specifications and technical parameters

Technical parameters of rotary friction module

1. Test force range: 60~3000N, test force accuracy: ±1%

2. Maximum friction force: 500N, friction force accuracy: ±1%

3. Friction torque measurement range: 0-7.5Nm, automatic display and record value

4. Main shaft speed range: 1~3000r/min, speed measurement accuracy ±1r/min, Panasonic servo infinitely adjustable

5. Temperature measurement and control range: room temperature ~800℃, temperature measurement and control accuracy ±2℃

6. Test medium: air, oil, water, mud, abrasives, etc., with stainless steel mud tank, can achieve the environment test of abrasive wear, adding sand mud, weak corrosive medium at will

7. Time setting: 1s~9999min

8. Form of friction pair: pin disk, end face, ball disk sample

Technical parameters of reciprocating friction module

1. Test force range: 5-60N, test force accuracy ±1%

2. Friction measurement range: 50N, friction accuracy ±1%

3. Friction pair form: O-ring-metal plate reciprocating friction form

4. Load form of test force: weight loading

5. Reversal displacement amplitude: 10mm/15mm/20mm, adjustable

6. Maximum reciprocating stroke: 40mm

7. Repeated test frequency: 0.1-5Hz can be adjusted arbitrarily

Key words