TIME3221 Roughness Tester: Technical Features, Application Scenarios, and Future Outlook

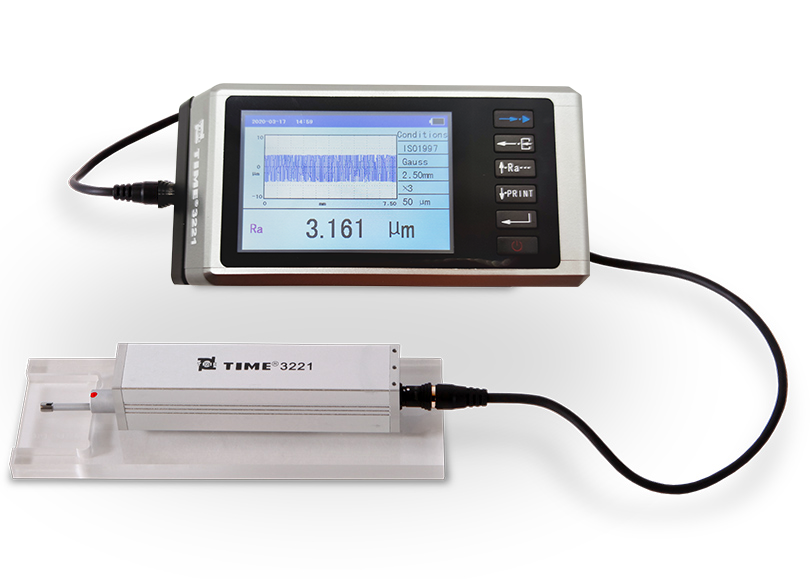

TIME3221 high-performance roughness tester, a high-end surface quality testing device launched by Beijing TIME High Technology Co., Ltd., represents the advanced level of roughness measurement technology in China.

The instrument utilizes a separate main unit and driver design, successfully increasing the sensor's vertical measuring range to 400μm, significantly enhancing its ability to measure surfaces with significant irregularities. This design concept reflects the trend of "specialized functions and user-friendly operation" in the engineering instrument industry, ensuring both measurement accuracy and increased flexibility in field applications.

The instrument's core utilizes inductive stylus sensing technology. A diamond stylus slides along the surface under test with a constant measuring force of 4mN. By detecting the vertical displacement of the stylus caused by microscopic surface irregularities, it drives the magnetic core to move synchronously and changes the inductance of the differential inductor coil.

The resulting electrical signal undergoes phase-sensitive rectification, digital modulation, and demodulation. A DSP chip then performs refined filtering and parameter calculation, ultimately displaying the roughness curve and a full family of parameters in real time on a high-resolution color touchscreen. This measurement process adheres to international standards such as ISO 1997, ANSI, and JIS 2001, ensuring the authority and comparability of the data.

TIME3221 is designed with the demands of complex industrial environments in mind. The instrument features a portable design, measuring just 155.4mm × 75mm × 53mm, weighing approximately 580g, and the driver weighing only 165g. This compact design not only allows for easy portability but also adapts to various measurement tasks in confined spaces and complex environments, providing stable and reliable measurement services from the laboratory to the production site.

TIME3221 roughness tester's technical performance is reflected in its precise measurement capabilities and wide adaptability. The instrument supports the calculation and display of all ISO R-family parameters (such as Ra, Rp, Rv, Rt, Rz, Rq, Rsk, and Rku) and the entire P-family of profile parameters, providing comprehensive surface property data in a single measurement.

Furthermore, the instrument supports the measurement of specialized parameters for automotive sheet metal, meeting the specialized needs of specialized industries.

Applications and Test Cases

The TIME3221 roughness tester, with its superior technical performance, has been widely used in various industrial fields, becoming a key tool for surface quality inspection.

- Aerospace

In the aerospace industry, the surface integrity of high-temperature alloy components such as engine blades and turbine disks is directly related to product performance and safety. The TIME3221 can accurately measure the surface roughness of these components after special processing, ensuring that they meet the stringent requirements of aerospace. For example, measurements of the tongue and groove area of a certain engine blade showed that the Ra value was stably controlled within the range of 0.4μm ± 0.05μm, and the Rz value remained at 3.2μm ± 0.3μm, fully meeting design specifications.

- Automotive Manufacturing

The automotive industry has extremely high requirements for component surface quality. Whether it is transmission components such as gears and bearings, or the exterior surfaces of interior parts, precise roughness control is required. The TIME3221 can be used to evaluate the surface finish and wear resistance of these parts, providing data support for quality control. A gearbox gear manufacturer implemented the TIME3221 for online inspection, reducing product defect rates by 12% while improving inspection efficiency.

- Precision Machining

In the mold manufacturing and precision machining industries, the TIME3221 is used to verify the polishing effect and coating adhesion of mold steel and carbide. By measuring P-group parameters, the instrument can comprehensively evaluate the functional properties of the surface and predict the wear life and fit performance of parts. A precision bearing manufacturer used the TIME3221's profile measurement function to successfully resolve bearing noise issues, reducing the defect rate from 8% to 0.5%.

- Electronic Devices

As electronic devices evolve towards miniaturization and higher precision, the demand for surface quality of tiny parts is becoming increasingly stringent. The TIME3221 can screen for surface defects in tiny parts such as high-precision connectors and sensors. Combined with dedicated hole and groove sensors, the instrument can even measure the internal roughness of holes as small as 1mm in diameter, solving the challenge of inspecting tiny parts in the electronics industry.